A large tank manufacturer supplies their military and defense customers with critical weapons of war, and before delivery of the equipment they must provide training on how to use them. Weighing in at over 50 tons (*M1 Abrams tanks weight between 67.6 and 73.6 tons) and costing upwards of $4 million (UK Challenger 2 tanks cost around $4.9 million and German Leopard 2 tanks fall around the $6 million mark*), not to mention the potential for personal injury, training customers for the first time in an actual tank is extremely risky and not an option.

*[SOURCE: Newsweek article "From Abrams to Leopards: The Cost of Western Tanks Being Sent to Ukraine"]

https://www.newsweek.com/cost-western-battle-tanks-m1-abrams-leopard-2-challenger-2-1776725

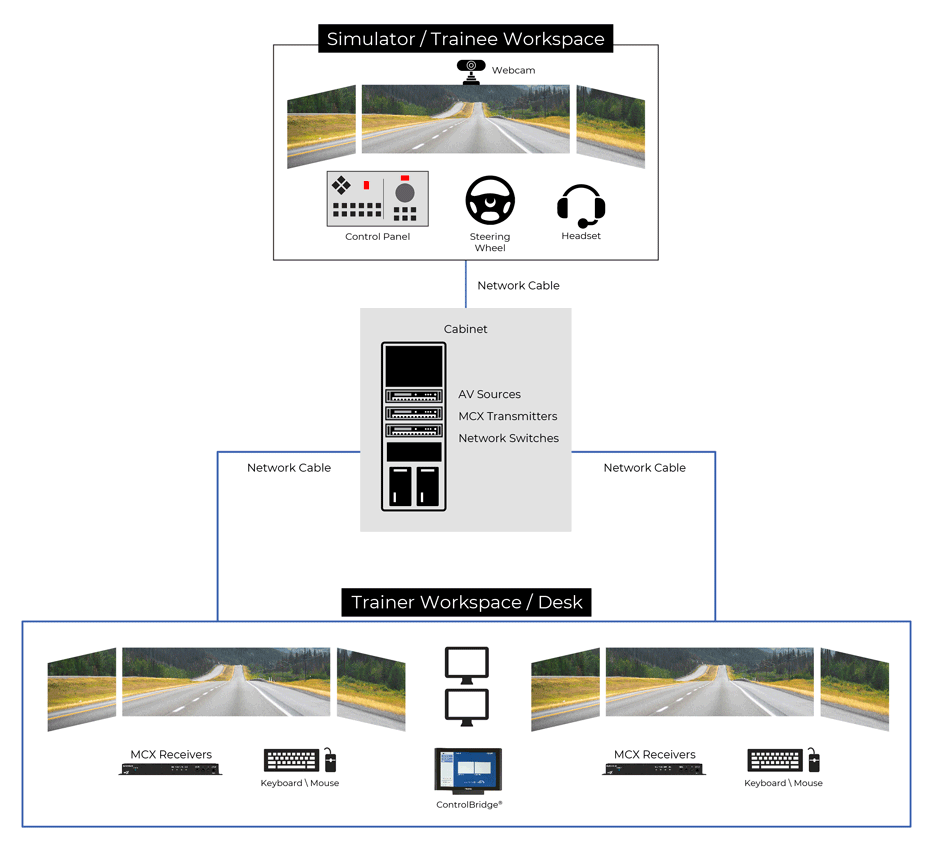

To avoid this, the tank manufacturer requires a real-world simulation environment to train their customers in. This simulation replicates the scenarios their customers will experience in reality, with cabins being created to mirror that of the tank, including hydraulics to replicate feel, controls to operate it, and displays that present real life battlefield environments to train in and which present real-time responses to actions. These responses are monitored by a trainer located at a control station that is separate to the simulation chamber. This station features additional displays that duplicate what the trainees see and their reactions to the simulation, allowing the trainer to manipulate the environment as needed and speak to the trainees in real time. Soldiers are thus enabled to simulate every possible combat situation along with the associated stress management inherent to tank operation, and they can do so in a controlled environment that does not risk personal injury or damage to the actual equipment.

To create their tank simulation system, the manufacturer designed the software required to drive it, and then procured hardware that could distribute through extension, splitting, and switching the ultra-high performance audio/video for display to trainers and trainees. With instantaneous transmission being essential to duplicating a real world environment, the manufacturer previously utilized individual hardware extenders, switches, and splitters that connected source equipment to displays via standard AV cabling to provide minimal latency. This setup was complex and introduced extra effort and length constraints when routing the necessary cabling, and it was complicated to manage the various video hardware components, which were not designed to work seamlessly in unison. Therefore, it became a primary objective for the company to find a new all-in-one solution for distributing the audio/video used in their training simulators. The system needed to eliminate the constraints of their current system of individual hardware components, while delivering ultra-high definition video and audio with instantaneous reaction time to provide the required real-world environment, as a mere millisecond delay in response could lead to an unfavorable outcome on the battle field.

Having a positive experience working with Black Box on product solutions in the past, the company reached out to us for help in solving their simulation conundrum. We immediately set to work and our solutions architects provided multiple options from our range of Audio/Video and KVM solutions, which prompted the company to choose Black Box to supply the solution in the form of our MCX AV over IP Video Distribution products.

Of the solutions provided by the Black Box team, the MCX AV over IP Distribution products stood head and shoulders above the rest in terms of its ability to satisfy all customer requirements for their tank simulation system; in particular its real-time (< 0.03 milliseconds) glass-to-glass encoding and decoding capabilities.

The Black Box MCX AV over IP system proved to be a perfect fit, providing an easy-to-deploy solution that reduced the cabling installation constraints and distance limitations of standard cabling products. As an all-in-one solution, it shrunk the SKU count considerably, reducing the number of required components to three devices: transmitter (encoder), receiver (decoder) and controller. They connected all of their video source devices to MCX encoders and their displays to MCX decoders. These endpoints were all networked together through a network switch that provided connectivity for the entire system. The MCX controller was then connected to the network, giving them complete control of their system and allowing them to distribute their video sources to any display(s) required, to present content in a video wall format across multiple monitors or provide multiview display with picture-in-picture, all while managing the security of their system by limiting access to only specified users.

The resulting MCX solution provided the all-in-one unification the customer was seeking, combining the extension, switching, and splitting functions they required by the simulators into a single system of products that were designed to work together seamlessly. An easy to install system, MCX allowed for all components to be connected to a PoE network switch, providing connectivity to the system while also powering the endpoints and eliminating bulky external power supplies. With the MCX controller they were able to easily distribute all of their audio and video content to the desired displays, while displaying content in a video wall format where needed. All of this was achievable while also meeting the customer's requirement for 100% accurate performance with instantaneous video transmission, as MCX is a zero latency solution that provides real-time (< 0.03 milliseconds) glass-to-glass encoding and decoding.

With this solution, the company was able to accurately and effectively replicate real-world conditions with their tank simulators, providing an authentic training experience for trainees to prepare them to operate the tank and to react quickly to the hazards of war. The simulation video and audio was simultaneously provided to both trainee and trainer over the network, allowing supervisors to monitor the simulation and to talk to the trainees during the training. Because it works with 4K, multi-view, video wall, and other setups, the MCX AV over IP system gives the client the ability to implement new features and capabilities into their simulation environment in the future without having to buy a different system.

With that in mind, the client is working on designs for future projects, and due to the positive experience and success they have experienced with MCX, they plan for this line of products to be their solution of choice for all similar simulations. With the launch of the brand-new MCX Transcoder that can be used as either transmitter or receiver, they have a great new tool to use in simplifying their AV over IP Distribution system.

About the MCX product solution, the customer said, "It is overwhelmingly easy and we plan to use it for all major new releases."

Industry: Military & Defense,

Products: MCX AVoIP 10G 4K, ControlBridge® Control System,

Technology: AVoIP,