The evolution of the data center has changed with the demand of fiber connectivity increasing over the years. When fiber was first used in the data center many years ago, it was minimal. There were only a few duplex fiber patch cables in use, unlike today where there are huge bundles of fiber trunk cables.

With space in the data center always in high demand, fiber connectivity has continued to evolve from the bulky ST and SC connectors to the smaller LC (SFF, Small Form Factor) connector. This is great for equipment that requires two-strand duplex fiber patch cables, but fiber cabling sometimes requires running bundles or groups of fiber strands from one point to another throughout the data center or within a data cabinet. This is where a user can take advantage of an MPO connector.

The MPO "Multipath Push-On" connector was developed into a standard (IEC 61754-7) many years ago with the anticipation of running many fiber strands end-to-end in a quick and easy way. The MPO is a polymer body based connector that can commonly support either 12 or 24 fiber strands and uses a keying and alignment pin system that is somewhat different when comparing it to duplex fiber connectivity.

The MPO connector is a system in which 12 or 24 fibers lay in one connector and can get passed end-to-end easily, unlike working with 6 or 12 duplex sets of bulky fiber connectors that can tangle easily and require more space. Because all the fiber strands are in one connector, the user working with MPO connectivity now needs to be aware of connector keying and genders.

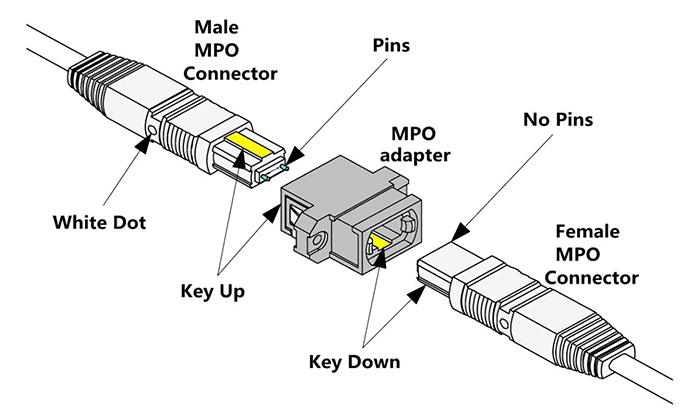

MPO "keying" is important because it helps ensure that the fiber strands get passed end-to-end across the channel the way the user wants. If the key was not on the connector, the user could insert the MPO "upside-down" and accidently pass fiber strand 1 to fiber strand 12. MPO connectors define and use the terms "Key Up" and "Key Down" to help installers understand this system. Also, to help identify fiber strand 1 on the MPO connector, there is a white dot on the connector side. So, the keying helps provide a way to manage the fiber connectivity end-to-end. (See the yellow area in the image above.)

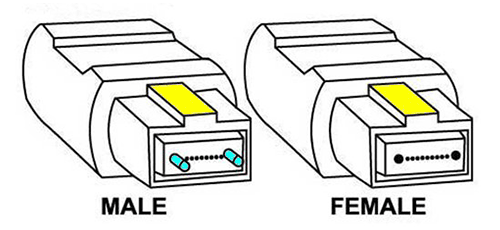

MPO "gender" is also very critical in this connectivity system. All MPO connectors use an MPO "adapter" to join MPO cables together. Because of this, an MPO cable with a male connector must mate with an MPO cable with a female connector. This is extremely important because the MPO male connector has two alignment pins that will insert in the MPO female connector's alignment holes. This guarantees that the 12 or 24 fiber strands line up properly with little dB insertion loss. (See the MPO adapter in the image below in gray.)

Technically, two MPO female connectors can mate through an MPO adapter, but you will not have good fiber connectivity. Actually, you will probably not pass any light between the two mated cables. The alignment pins on the connector ensure that the 12 or 24 fiber strands properly align. (See the alignment pins in blue in the image above.)

With this all being said, the MPO connectivity system can begin to have many combinations of trunk cable assemblies consisting of several keying and gender types, not to mention the vast number of possible lengths for each type.

Some companies have made improvements or enhancements to the standard MPO connector. One company that has done this is US Conec. Years ago, this company used the standard MPO connector design and made enhancements to it and called it the MTP connector. The standard MTP connector developed by US Conec is 100% compatible with the original MPO connector. They just made some enhancements that improved the overall insertion loss and durability of the connector. This was great and was widely accepted by the industry, but it at that time did not address consolidating any gender or polarity issues.

Recently, US Conec again made some improvements to their patented MTP connector that would allow users out in the field to change the MTP connector's gender and polarity for various applications. This from US Conec is what they call the MTP "Pro" connector.

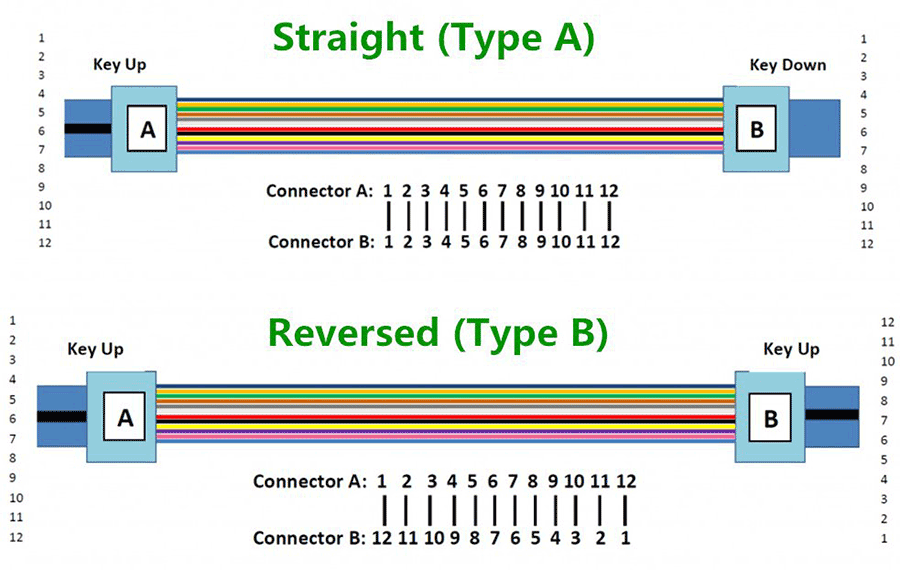

The MTP "Pro" connector on the end of a trunk assembly, with the aid of a small hand-held tool, allows the installer to make gender trunk changes (male-to-female) by removing the alignment pins or (female-to-male) by adding the alignment pin out in the field. Also with the same tool, the installer again out in the field can change the trunk cable's polarity. So the installer can convert a (Key Up to Key Down) Type "A" trunk assembly, which is pinned straight-through, to a (Key Up to Key Up) Type "B" trunk assembly, which reverses the fiber strands.

Because these fiber trunk assembles are rather expensive and usually made to order, this is a huge advancement in how they can be used. It allows the field installer to re-purpose them and use them in many ways as their application may change. This saves money, reduces the number of cable configurations, and ultimately lets the installer re-use them in future applications.

Early on, bulky fiber cable connector types such as ST and SC were replaced by smaller LC connectors to run two-strand fiber cable. Next, came the MPO connector, used for bundles or groups of fiber strands, followed by US Conec's proprietary MTP connector, which improved insertion loss and durability while remaining 100% compatible with the MPO connector. But even with MTP, polarity and gender are important to consider. More recently, to enable keying and gender changes in the field, US Conec developed the MTP Pro connector, which can also be re-purposed to suit a wide range of applications.

Product Engineer

Steve Molek has 27 years’ experience in the cabling and connectivity data communication industry. He started his career as a Technical Support Representative and now works as a Project Engineer for Black Box. As a Product Engineer, his primary focus is evaluating and testing all new cabling and connectivity products for sale by Black Box and training our inside technical support and sales teams. Steve also works directly with our domestic and international OEM suppliers as well as several nationally recognized third-party testing labs. Steve holds a B.S. degree in Mathematics and Computer Science from California University of Pennsylvania and an MBA from Waynesburg University.