Twisted pair cabling has been around for many decades. It has become the cabling type of choice for all networking applications going back to when it was first introduced back in the early 1990’s. The first application using twisting pair cabling was with the very slow 10Base-T which was only a 10 Mbps application. Today twisted pair applications can support high speeds up to 10 Gbps. So with such an increase in networking speed a question you may ask, is all twisted pair cabling the same? Absolutely not. Twisted pair cabling may all look the same from the outside jacket, but there is a lot of internal technology inside that is unseen to the user.

The most common form of twisted pair cabling typically has four pairs. Internally the four pairs follow a common color code standard set by ANSI/TIA 568.2-D which is

Pair 1 – is a Blue wire twisted with a White/Blue wire

Pair 2 – is a Orange wire twisted with a White/Orange wire

Pair 3 – is a Green wire twisted with a White/Green wire

Pair 4 – is a Brown wire twisted with a White/Brown wire.

But that’s about where it ends. But what sometimes gets overlooked is inside the cable jacket there is lots of technology and engineering which affects the performance and networking speeds of the cable.

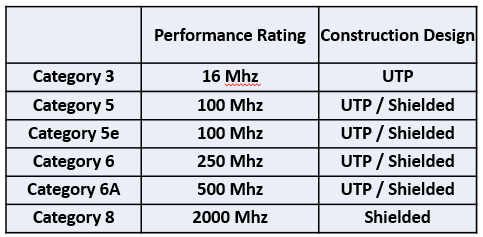

Over the years, there has been many different types of twisted pair cabling. These are available and comes in many different performance ratings and construction types.

Performance ratings are identified by category types. The first true “data grade” of twisted pair cabling was called Category 3. Prior to this, any form twisted pair cabling was not considered data grade. Today the highest ratified cable category governed by ANSI/TIA is Category 8. The higher the cable category the better the cable performance. The cable performance is noted by the increase in megahertz rating for the cable. The Megahertz (MHz) rating states on how fast a signal can be sent through the cable and still be acceptable on the far end.

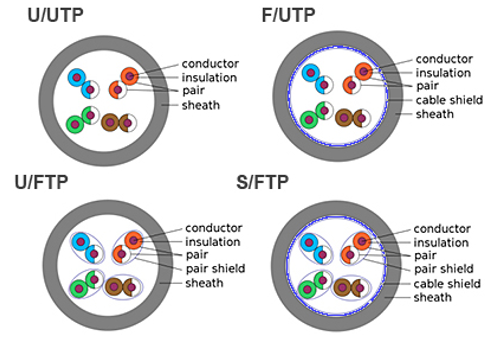

Construction types of the cable categories can vary from a basic un-shielded twisted pair cable (U/UTP) to a wide range of shielded designs. While un-shielded twisted pair is the most commonly used construction type installed in the market place, there is several different type of shielded twisted pair that are available. This varies because there are several ways the shielded can be applied to the overall cable and individual pairs.

There are several common types of shielded twisted pair cable available for a cable category. Since there are several ways to “shield” twisted pair cable, you will need to understand the notation on how the shielding s applied to the cable. Shielded cable is typically written as (F/UTP), (U/FTP) and (S/FTP). Notice the “/” in the notation. On the left side of the slash represents the overall shielded around the 4 twisted pairs. On the right side of the slash represents the shielding for the individual pairs.

(F/UTP) – Refers to 4 un-shielded twisted pairs surrounded by some form of overall shielding in a cable jacket

(Sc/FTP) – Refers to 4 individually shielded pairs surrounded by some form of overall shielding in a cable jacket

(U/FTP) – Refers to 4 individually shielded pairs without any overall shielding in a cable jacket

Shielded cable is commonly used in applications where there may be some un-controllable exterior noise sometimes referred to as (EMI/RFI) which could cause interference to your network. Regardless of the type of cable construction, there are many internal factors which control the level of performance from the cable. So with all that being said, “What are some of the internal cable engineering used to achieve these higher performance standards”? Some of these are:

Internal Pair Twisting – Is probably what everyone notices first when it comes to twisted pair cabling. This is represents by twisting 2 wires together for the purposes of canceling out electromagnetic interference (EMI) from external sources. Normally when a signal is sent across a wire it begins to weaken or attenuate and also begins to generate noise. A way to help better assure of getting a good signal over long distances, engineer’s will send a positive and negative of the same signal each on its own wire and twist them together. The signal will still attenuate, but any positive and negative noise made will cancel out over the length of the cable.

With that being said, the higher the twisted pair cable category which supports a higher megahertz rating, the tighter the pair twisting. The greater the pair twisting within the cable has a positive effect to the NEXT, Near-End Crosstalk electrical measurement. For example, Category 3 cabling can have 2 or 3 twists per foot while Category 6 or Category 6A cabling can have up to 20 to 25 twists per foot depending upon the pair inside.

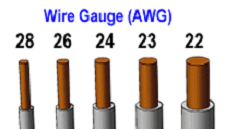

Conductor Core – Cable performance is more than just the twisting of pairs with in the cable jacket. The size of the conductor core also greatly affects the performance of the cable. The size of conductor wires are measured in gauge which refers to American Wire Gauge, (AWG). AWG is sized by the number of times a wire is drawn. For example: a 28 AWG wire is thinner than a 22 AWG wire, because it was drawn more times thus the wires will be thinner.

The electrical measurement that’s most affected by the size of the conductor core is attenuation. Attenuation, now of days it’s often referred to as Insertion Loss, which is the measurement of the signal through the cable. The thicker the wire conductor has a smaller wire gauge and usually less signal loss. The thinner the conductor has a higher wire gauge and usually higher signal loss.

Typically Category 5 and Category 5e horizontal solid cables are use a 24 AWG conductor in their construction. Category 6 and Category 6A horizontal solid cables will use a 23 AWG conductor in their construction.

With all that being said, bulk cable manufacturers need to be careful when “sizing” the conductors in their cables. Too big of a conductor can hurt the cable performance. Sure the signal strength is very good, but because there is more copper inside the cable the NEXT measurement decreases because the conductors act like an antenna within the cable and more crosstalk occurs. Not to mention that un-necessary use of larger wire conductors adds to the overall cable cost.

As you can see, it can become a balancing act for cable manufacturers when engineering and designing cable between the pair twisting and conductor core size. But cable manufacturers have found a way around this to still use both of these cabling design techniques and get maximum performance.

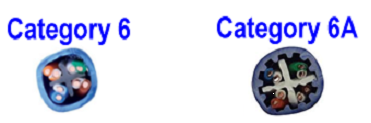

Pair Separators – Another performance enhancing feature that bulk cable uses is the use of some form of a pair separator. Pair separators come in several forms, either a “X” design cross filler or a simple tape filler. See image below. These fillers are used to create space or some form of separation between the four twisted pairs inside the cable. Twisted pair separation is important because it improves the NEXT, near-end crosstalk electrical measurement of the cable. This is especially critical with higher speed Category 6 and Category 6A data cables.

Manufacturers have found that by adding filler inside the cable, they still can still tightly twist the pairs and even use thicker conductors and still keep the overall performance to the desired cable category requirements. The “X” design cross filler is extremely common because it equality separates all four twisted pair the same. The tape filler is used, if the manufacture fills they need to have a barrier between only two of the four twisted pairs within the cable. Fillers are very useful in cable design, but the negative factor when using them is they bulk up the cable by making the overall cable diameter larger and also adds more cost to the cable with additional material and manufacturing time.

Insulation and Jacket Materials – Another design technique that must be considered in the manufacturing of high speed data cables is with the insulation and jacket materials. Many users overlook or don’t realize how important this actually is. There is actually several critical factors involved with the materials used in making of a “good” cable. This is a two part topic which deals with cable performance and a burn safety testing.

When it comes to insulation and jacket material the thickness of these materials dictate the cable performance and flexibility of the cable. If the insulation materials are too thin, this means the conductors are closer together and could affect the NEXT cross talk measurement of the cable. If the insulation is too thick then it hinders the flexibility of the cable, plus adds cost and size to the cable. Referring to the cable jacket, this is also true with one exception. Category 6A bulk cables usually have very thick or un-usual shaped cable jacket designs. This is to purposely create additional spacing when one cable is side by side another. Since Category 6A is concerned with ANEXT, Align Near-end cross talk, noise outside the cable manufacturers will “bulk up” or make the jackets thicker to achieve this level of performance.

When it comes to data grade twisted pair cable, everyone usually thinks of the cable performance only. There is a safety factor that must be considered as well. Every twisted pair data cable is made and design to meet a specific installation. This means where the cable can be installed legally according to the local building and fire codes within a jurisdiction. This can be a very complex topic subject. But what is important here is the type of compounds used in the making of the insulation and jackets. Depending upon the type of burn test that the cable needs to meet, the compounds can be very expensive.

For example, twisted pair cable that is installed in overhead air spaces typically requires a plenum rated cable. A twisted pair cable that meets plenum rating, must use some very specific and expensive compounds. One of these compounds used on the insulation of plenum cable is FEP, fluorinated ethylene propylene material. This material is very expensive and which can greatly affect the final cost of the cable, so manufacturers try to use just enough of this material to stay competitive, but still meet and pass the strict burn test while keeping the cable performance.

So between meeting the desired cable performance and burn testing, the thickness of the cable insulations and jackets can become very critical and become a balancing act in the overall final design and production of the cable

Finally, as you can probably see, designing a category rated data cable is not just putting a few twisted pairs inside a cable jacket. There’s a lot of internal engineering that goes in a cable to achieve a specific performance, while still maintaining a desired cost and still be able to meet any required testing while having a product that is accepted by the industry. In many cases, when manufacturers are designing a cable, they will correct or improve one feature and hurt or hinder another necessary feature of the cable at the same time. So many cable prototypes are made along with lots of testing go in to making a good performance cable. Hopefully this gives you some inside on what all goes into making bulk cable as you make your next purchase.

Product Engineer

Steve Molek has 27 years’ experience in the cabling and connectivity data communication industry. He started his career as a Technical Support Representative and now works as a Project Engineer for Black Box. As a Product Engineer, his primary focus is evaluating and testing all new cabling and connectivity products for sale by Black Box and training our inside technical support and sales teams. Steve also works directly with our domestic and international OEM suppliers as well as several nationally recognized third-party testing labs. Steve holds a B.S. degree in Mathematics and Computer Science from California University of Pennsylvania and an MBA from Waynesburg University.